EDM 101:

Optimizing RAM EDM Process for Economic Efficiency

Our Goal: Engineer and Deliver a Product for Manufacturers of Precision Parts to Remove Broken Tooling as well as Produce Basic Machined Features In-House using EDM Sinker Methods

Operational benefits ranging from cost-effective tap burning to streamlined broken-tap extraction make the EDM-101 a wise decision for any machine shop or tech school. Among the most versatile EDM advancements in the industry, our adaptable electrical discharge machine is a great supplement to existing EDM processes, cost-effective roughing, and any business hoping to optimize their broken screw removal needs. Also a dependable choice for any shop or school that could benefit from entry-level electrical discharge processes, our user-friendly EDM-101 offers multipurpose compatibility for low-volume part production, hex nuts, spiral screws, keyways, and so much more.

Cost-Effective EDM: Smart Spending, Great Results

Better EDM machining processes tap into a range of unexpected benefits. Instead of facing production delays while waiting for an outsourced roughing project or stripped screw removal, our affordable EDM machines empower your team to manage a greater range of intricate project types.

With our ultra-efficient tap burner, you shield your bottom line from several production risk factors. Our optimized electrical discharge sinker never makes physical contact with the workpiece, resulting in reduced material waste, a safer workplace, and ease of producing intricate hex and cylindrical components without exposing your tools or the component to traumatic impact forces.

Even if you already have a fully capable CapEx sinker or Bridgeport setup, the EDM-101 is the perfect addition to any shop. Instead of halting production to handle a basic tap removal or part roughing task, utilize our cost-saving EDM machine to handle all entry-level sinker projects with precision. These useful application benefits also apply to tech school demonstrations, reduced time-to-market, and ultimately, superior quality components made from any conductive material.

Products & Services

Contact Us Today to Learn More About EDM 101 capability.

| HEAD ASSEMBLY | Included functionality |

| Quill mount bracket | Tool-less Dutch key for easy On/Off & Rotation |

| Built in HEAD swivel for veritical orientation | |

| + 7″ added to the Bridgeport work envelop | |

| + Rigid design supports additional custom orientations | |

| Z Axis | Full 75mm (2.95″) Travel |

| Built in Electrical contact detect : XYZ sound annunciator | |

| AutoStop : Operator selectable Depth (blind) and Material thickness | |

| Precise positional control | |

| + Full Up/Down jog control with 0.001″ resolution | |

| + Easy to customize coarse and fine jog based on your desire | |

| Full positional control of Pecking | |

| + Fixed, Surface, and Combined Fix & Surface Pecking | |

| + Example : 0.020″ peck every 5 seconds | |

| Programmable electrode wear compensation for repeatable accuracy | |

| Fully automatic 1.0 micron resolution during EDM operation | |

| Theta Axis | Sweep range programmable 0-270 degrees |

| + Face of round electrode remains flat and predictable | |

| + Sweep eliminates “tails” from forming when remoiving Taps | |

| Note : Other Tap burners require periodic refacing to remove “Tail” that can damage blind holes | |

| Unique theta offset function supports electrode orientation to 0.1 degrees. | |

| + Ensures orientation repeatability when job requires multiple shaped electrode operations | |

| Flushing | Integrated spindle port for core flush fluids |

| Industry standard 8mm grommets support 0.5-5.0mm flushing electrodes | |

| Color display | Easy to observe current active job state .. Complementing Tablet Real Time Display |

| ESTOP | Instantly disables motors and EDM voltage output |

| Wifi | Self contained Wifi node supports communication with Tablet-App |

| FCC compliant | |

| End effector | Compliant with Multiple Chuck Adapters : J1, 5-16/24, 3-8/24, CMW rod and shaped electrode adapters |

| Built in referance pin allows accurate electrode changes and re-alignment repeatability | |

| Adaptor Nut makes for easy on/off adapator changes | |

| Attachment | Electrode guide assembly (option) holde industry available small hole guides |

| POWER CONTROL UNIT | Included functionality |

| Electrical Connections | AC Line Input |

| + 220 VAC Single Phase, 20A line | |

| Separate Positive and Negative Polarity Ports | |

| + To Electrode / From Ground return | |

| + 0.325A to 20A EDM current | |

| + Precise On & Off time modulation of current according to Job parameters selected (usec resolution) | |

| + Gap voltage automatically monitored to maintain Electrode position for EDM | |

| + 120V at Gap | |

| + Low Voltage contact detect. Selectable in Table Setup | |

| Shielded DB25 | |

| + Receives Host Tablet commands | |

| + Outputs position control of Z and Theta axis to support Joging and EDM process | |

| + Outputs periodic status of all functions for Tablet display | |

| Pump Cable | |

| + Pump 1 12V : Side flush using submerged pump in dielectric source | |

| + Pump 2 12V : Core Flush pressure boosted 5-100psi | |

| Annunciator notifies and alerts operator with audable sounds | |

| USB Port 5V charges Tablet | |

| Mechanical Installation | Robust Welded Steel Assembly Bolts to Bridgeport rear RAM mount |

| + Hanger forks extend through Top cover of PCU | |

| Table Top | |

| + Rubber feet standard |

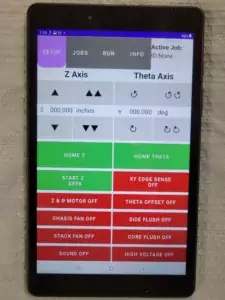

| TABLET | Android Tab A 8″ Tablet |

| Communication | Wifi |

| + Tablet detects Wifi Node in HEAD during power-up | |

| + Seemless wireless communication between Tablet and Head for Operations | |

| + User can change local wifi name as desired | |

| CMW Tech App | 4 Easy to Operate Modes |

| SETUP | Initial Setup and Manual functional check of Hardware |

| + Home : Z and Theta Axis | |

| + Jog : Z and Theta Axis, with custom resolution adjustment | |

| + Z-Seek auto detect surface position using low (<5) voltage through electrode | |

| + XY edge senses surface position using low (<5) voltage thorugh electrode | |

| + On/Off Side and Core Flush pumps | |

| + On/Off PCU Internal Chassis and Stack | |

| + Theta Offset adjustment | |

| + On/Off Sound Alerts from Annunciator | |

| + On/Off High Voltage to Low Voltage | |

| JOBS | Create new Jobs with unique ID, Names, and creation dates |

| + Duplicate , Rename, and Delete Jobs | |

| + Load (retrieve) and Backup Jobs on HEAD SD card | |

| Setup Parameters according the EDM requirements | |

| + Depth or Thru EDM Distance | |

| + Job Notes : Target Material, Electrode Material Shape and Size | |

| + Maximum Amps to use and On/Off Time for current selected | |

| + Theta : Sweep and Dither increments, range, and interval | |

| + Soft Start : Unique current and displacment control during beginning of EDM | |

| + Full Peck control : Fixed, and Surface displacment and interval desirred | |

| RUN | Start / Stop EDM |

| + On/Off selection of Side and Core Flush Pumps | |

| + Z-Zero : Operator can manually set Z Zero as desired | |

| + Z Position : : Actual, Z Minimum acieved, Z Min with Electrode Wear Compensation | |

| + Run Time Message Window : Alerts, and Temperature bar graph | |

| When EDM not active (Stopped) | |

| + Full Z and Theta Axis Jog Buttons for conventience without exiting mode | |

| When EDM active (Started) | |

| + Graphics showing Msec Counters spent Moving Down and Retracking | |

| + Graphic animation showing Electrode and Target Materials % Complete | |

| INFO | Monitor FeedRates and other monitored results for Process knowledge |

| + Sensor states, timers, performance counters, etc. show status of system in real time |

| FLUID ASSEMBLY | Deionized Water, Distilled, Reverse Osmosis and Tap < 150 uS/cm |

| Storage | 20 Gal. Capacity High Density Polyethylene Drum |

| + Recirculatory System | |

| Filters | PreFilter : 4″ x 14″ Seamless Polyester |

| + Course Swarf.. Recommending 5 micron rating | |

| + 0, 5, 10, 15 micron particle size filters available | |

| + Inexpensive (~$6) replacement | |

| + Mount designed to optimize gravity runoff vs. workpiece height | |

| Primary Filter : Pentek 10″ 3G Slim Housing Clear | |

| + Fine Swarf.. Recommending 1 micron rating | |

| + Inexpensive polystyrene or pleated (~$5) replacement | |

| Manifold | T-Slot Mount allows easy adjustment for both Core and Side Flush flow |

| + Integrated pressure gauge feedback for Core flush pressure | |

| Pumps | Primary Submersible : Side Flush Low Pressure |

| + 12V Heavy Duty Johnson / Albin Style Marine Bilge | |

| Secondary : Core Flush | |

| + 12V Diaphram Style Booster Modified 0-100psi | |

| + Pressure is adjustable through CMW valve desgin | |

| Secondary : Core Flush Vacuum | |

| + Valving switches Pressure across integraqted Venturi to create vacuum | |

| + Unique capability pulls swarf through electrode ID reducing side arcing | |

| Rust Inhibitor | Recommendation : Uniquely does not increase conductivity of water |

| + Savan RVH-650-1 | |

| Cart | Push Cart Dolly by Wellmax, 330 lbs capacity, Swivel wheels |

What is Electrical Discharge Machining & How Does it Work?

EDM is a non-conventional machining method that relies on electrical discharges to remove material from a workpiece. It’s the go-to choice when you need to produce, extract, or repair intricate components from extremely hard conductive materials like steel and titanium. Unlike grinders and mills that rely on physical force to shape a part, EDM innovation shapes parts with thermal energy that transfers between an electrode and the conductive material being machined.

First, an appropriate electrode is mounted on the quill-mounted EDM-101 Head, the operator enters basic objective parameters into our user-friendly tablet app. When the workpiece material is fixtured by the machinist/operator followed by setup of flushing nozzle the EDM process can commence.

Once the program commences, the electrode moves downward in Sinker fashion. Simultaneously, a dielectric water submersion/stream is applied to facilitate thermal energy transfer, cool the workpiece, and flush eroded debris away from the workpiece in the shape of the electrode.

After the operation is complete, the machinist cleans and inspects the part for defect-free accuracy.

EDM-101: Primary Benefits

Crafting intricate, delicate, or hardened materials that conventional tools are unable to shape safely or accurately makes the EDM-101 a dependable choice in every industry. Great for tech school demonstrators, practical staff education, and any shop that wants to cut costs on broken tap removals or low-volume part production, here’s how EDM-101 innovation can revolutionize your processes:

From predictable keyway production to ease of refinement after Bridgeport roughing, EDM-101 machining provides predictable production with every run.

Forget the pliers and grinders and rely on our affordable EDM machine to optimize your extractor needs. Easily remove broken power drill bits, embedded hex screws, and spend less on replacement products with every damaged part our EDM machine saves.

Whether you are hoping to impress future business partners, upgrade your curriculum, or empower your staff with easy-to-use equipment, our electrical discharge machine simplifies all demo and training needs.

Excited to explore other economical EDM applications for your shop or tech school? Our experienced machinists offer collaborative service and decades of machining insights for production and education needs in all sectors. However, we can help you integrate innovation, savings, and greater efficiency into your machining processes, don’t hesitate to reach out to our experts at CMWTech for professional guidance today.

- Prefer to process your Tap, Drill, and N-mill removal in-house?

- Have a Bridgeport or similar knee-mill in your shop that’s underutilized?

- Have a need to EDM sink simple shapes like a hex, square, keyway?

- Have a need to EDM a small hole in a high alloy part, such as a .020 dia. bleed hole?

- Have a need to EDM low volume simple shapes ?

- Hate having your specialized EDM machinist use a $150K+ Edm to remove a broken tool ?

- Find your part too large for your EDM but can fixture it on your Bridgeport or similar turret machine ?

EDM-101 is the most cost effective answer to Upgrade your classroom environment to teach EDM precision machining.

Trade school, tech shop or community college EDM equipment that not only demonstrates but performs precision machining equals value. Our EDM-101 is the most capable and affordable solution. Your program no longer has to compromise on entry-level EDM products that offer limited to no utility to inform your students the basic EMD process, or worse try to educate based on a text book alone. With EDM-101 EDM education demonstrator in place, knowledge of the EDMing process can be completely taught and tested.