Broken Bolt Removal Company

Before writing off another damaged product or piece of equipment, consider your broken tap removal needs solved with CMWTech on the cost-effective fix. The part-saving EDM services can extract everything from snapped dill bits and sheared studs, to hard-to-access extractions involving brokening fastening components that require a safer removal process.

Committed to accessible, affordable, and scalable drilling and milling malfunction resolution, removing damaged threaded components with greater precision is our specialty. To guarantee damage-free broken tap removal in Montgomery County, PA, our state-of-the-art EDM services are exclusively performed by expert machinists and the newest EDM systems in the industry.

Our Tap Removal process is as easy as 1-2-3!

to quote. Ship part or

advise drop-off to

receive turnaround

in same packaging

ensuring proper

handling

Contact Information

Looking For Tap Removal Services?

Industry Leading Tap Removal Services

When you require a deeply embedded fastener retrieval or removal of multiple sheared studs for dozens of valuable parts, our seasoned EDM pros never back down from a recovery project. However many broken bolt extractions you require, our cost-effective service model includes:

- Rapid turnaround times for machine shops, equipment manufacturers, and tech schools across the nation

- Competitive drill bit removal pricing for budget-friendly tap removal at a moment’s notice

- Support for any electrically-conductive materials; our threaded tool damage recovery processes are ideal for fragile/thin components as well as ultra-hard materials like steel and titanium.

- Aerospace-grade quality control: Precision is our promise at CMWTech. When you send us your parts for screw extractions and bore repair service, we treat your stripped threading and bore restoration project as if it was our own.

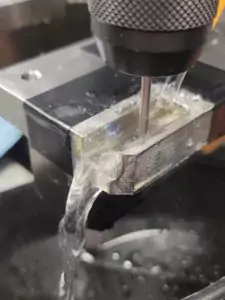

Watch Us At Work

What is Our Precise Broken Tool Removal Service:

We accept damaged parts from anywhere in the United States, or you can drop off your damaged parts at our convenient location in Pennsylvania. Once we receive your damaged parts, we evaluate, clean, and determine the best removal options for your specific material and part specifications.

Following our detailed inspection processes, we program the removal parameters into our CNC EDM machine. The part requiring extraction is stabilized within the EDM machine, then the pre-programmed electrode begins to erode the entrapped screw, bolt, or stud. Since EDM utilizes thermal energy to erode the trapped screw or bolt without physical force, we can safely clear drill bits and blockages without risking damage to the surrounding materials.

After extracting broken fastening components or the snapped drill bit, any remaining debris is cleared and the part is cleaned for final inspection. In many cases, we can simultaneously repair any adjacent problems such as metal burring for a component that functions like new. We then safely package and promptly ship your professionally restored parts directly to your door.

Looking to Remove Sheared Bolts?

Beyond the basics of threaded tool recovery solutions, our collaborative guidance includes support for a range of machine shop and part production needs. If you would like to improve your in-house fastener extractions or polishing processes, ask our team about purchasing your EDM-101 machine or environmental lapping slurry for streamlined shop performance.

Before exposing your valuable materials, tools, or equipment to a potentially-destructive removal process, contact our broken screw extractor pros first for cost-effective savings and operational peace of mind today.